Cline Machine and Automation, Inc.

FORMERLY SUBURBAN METAL PRODUCTS, INC.

FORMERLY SUBURBAN METAL PRODUCTS, INC.

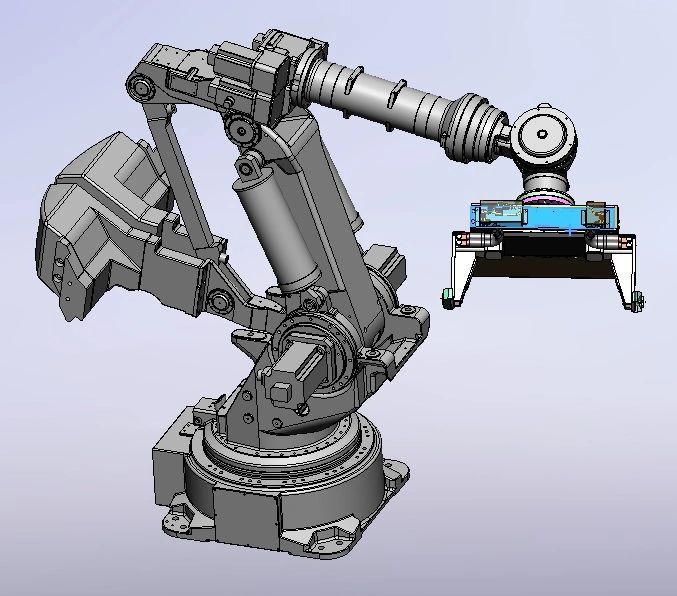

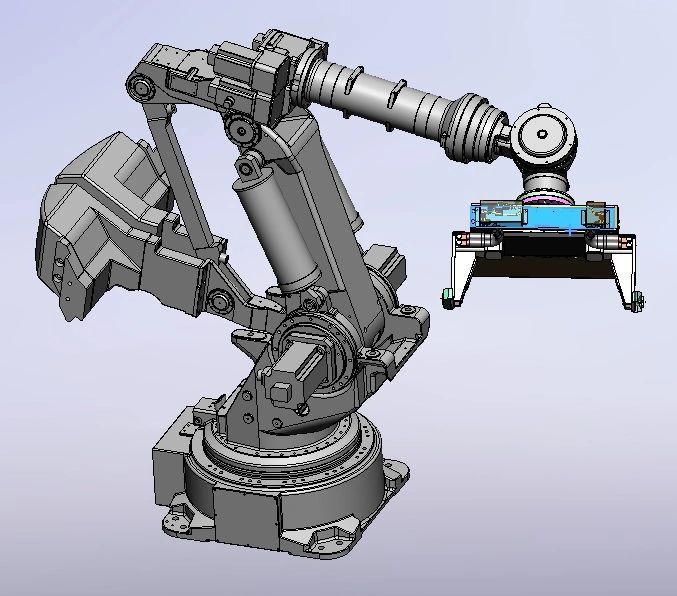

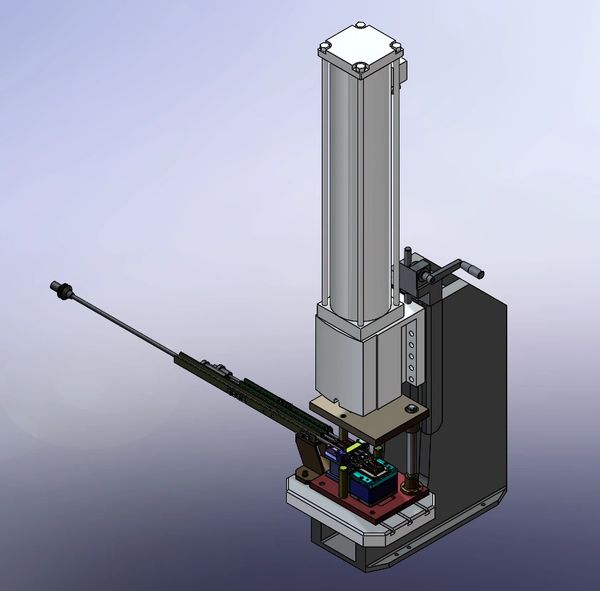

Cline Machine and Automation, Inc. (CMA) specializes in original mechanical designs and advanced metal working. Using 3D software, CNCs, lathes, welders and numerous other machines, we make parts for companies across the country.

CMA was founded in the late 1980's as Suburban Metal Products, Inc. (SMP). At first it was just a 2-man operation with a small engine lathe, a manual knee mill, and an old gear hob.

Through the 1990's larger manual lathes were added along with a number of knee mills with two axis DRO's. CNC was introduced in the mid 90's with the company's first Vertical Machining Center (VMC). More CNC's were acquired in the 2000's to further supplement the company's precision production capacity.

In 2010, the company was purchased by a local Mechanical Design Engineer and the company became CMA. More VMC's were added and a 3m x 1.6m CNC bridge mill was purchased as well. More importantly CMA added mechanical design to its offerings, supporting manufacturing and robotic integrators in the region.

Cline Machine and Automation, Inc.

Copyright © 2021 Cline Machine and Automation, Inc. - All Rights Reserved.